Explainable AI and Human-Centric Learning Solution Framework for Industrial Scheduling Optimization

The European steel industry is at a turning point. Faced with rising environmental demands and fierce global competition, manufacturers must find new ways to reduce energy use and emissions while staying competitive.

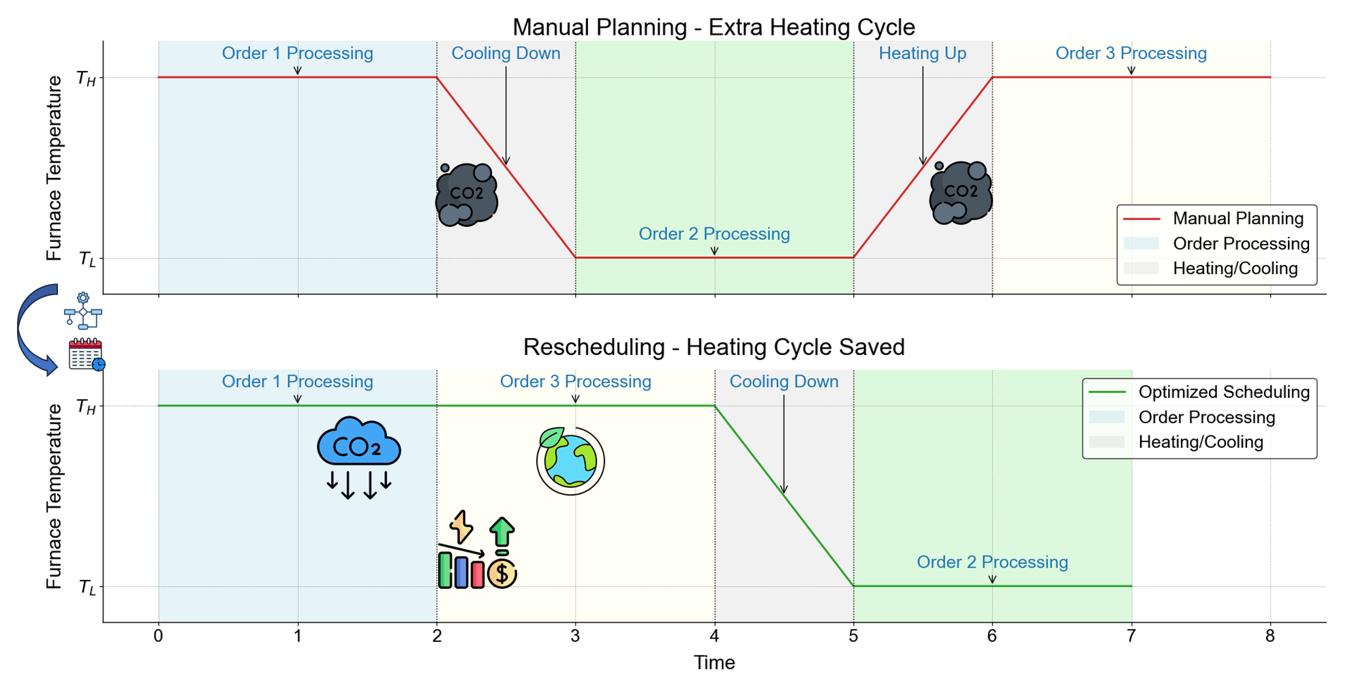

At the heart of this challenge lies heat treatment — a vital but energy-intensive step in stainless steel production. Today, manual scheduling methods often lead to inefficiencies, leaving furnaces idle for months each year and generating unnecessary CO₂ emissions.

Our project addresses this challenge head-on. By developing an AI-driven optimization framework for heat treatment scheduling, we aim to:

-

- Maximize furnace utilization and minimize idle heating time

- Reduce energy consumption and CO₂ emissions

- Adapt dynamically to real-time production changes

- Preserve expert knowledge through intelligent automation

Together, we’re forging a path toward a smarter, more sustainable European industry — where advanced optimization meets environmental responsibility.

We would like to thank the Research Fund for Coal and Steel of the European Union for the funding of this project, Grant Agreement No. 101216553, which is relevant for the future research in the steel industry.

We would like to thank the Research Fund for Coal and Steel of the European Union for the funding of this project, Grant Agreement No. 101216553, which is relevant for the future research in the steel industry.