Towards Smarter, Sustainable Steel Production

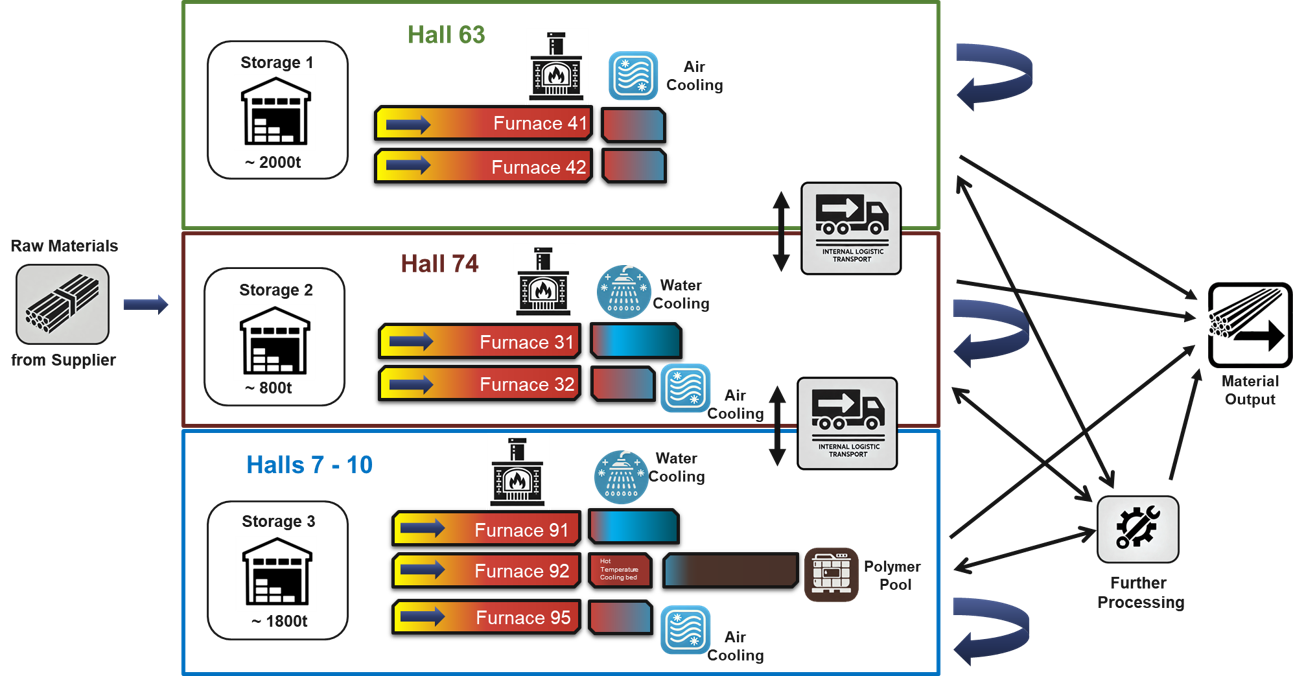

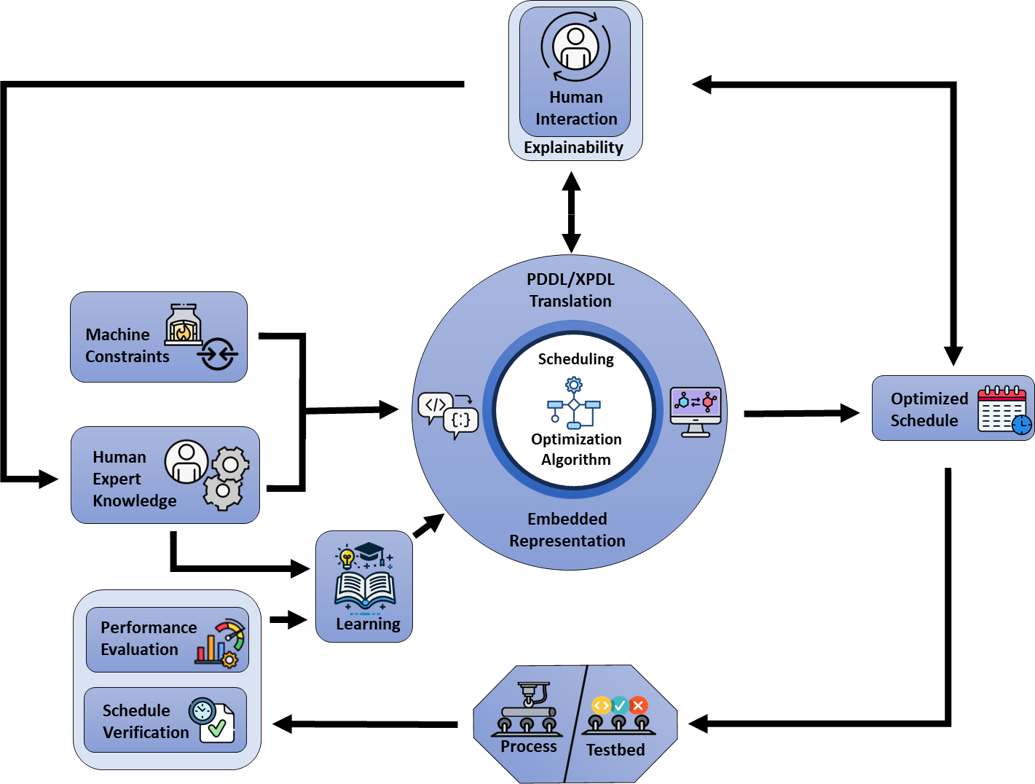

The project aims to enhance the flexibility of production scheduling and reduce CO₂ emissions in long steel manufacturing by developing DeepScheduling — a learnable, real-time AI-driven scheduling optimization framework for energy-intensive heat treatment processes.

By intelligently generating optimized production plans, DeepScheduling will help steel plants make better use of their furnaces, minimize idle heating, and significantly cut energy consumption and emissions. The concept will be demonstrated in long steel production environments, where multiple heat treatment routes and high process variability pose major challenges.

Understanding the Challenge

Heat treatment scheduling is a complex and dynamic process that requires the coordination of chained furnaces operating under strict temperature, timing, and safety constraints. Effective scheduling must account for:

- Dynamic production requirements — fluctuating orders, delivery deadlines, and changing workloads

- Operational constraints — furnace capabilities, temperature profiles, maintenance needs, and safety rules

- Uncertainties and disruptions — unexpected breakdowns, urgent orders, or supply delays

- Energy and sustainability goals — reducing unnecessary heating and cooling cycles to lower CO₂ emissions

- Process nonlinearity — variable heating and cooling times dependent on temperature

The DeepSC Approach

DeepScheduling integrates state-of-the-art scheduling algorithms, AI learning capabilities, and human expertise into one adaptive system. It provides:

- An intuitive Human–Machine Interface (HMI): enabling operators to explore alternative production routes and perform What-If simulations.

- Continuous learning from human input: the system evolves over time by learning from operator decisions, blending automation with expert knowledge.

- Benchmarking and hybrid optimization: multiple scheduling algorithms will be developed, tested, and combined to identify the most effective approach for complex industrial environments.

Impact and Innovation

Through the DeepScheduling framework, the project seeks to move beyond traditional manual planning toward a data-driven, adaptive, and sustainable production model. This innovation will improve operational efficiency, cut emissions, and serve as a model for other energy-intensive European industries seeking smarter, greener production strategies.